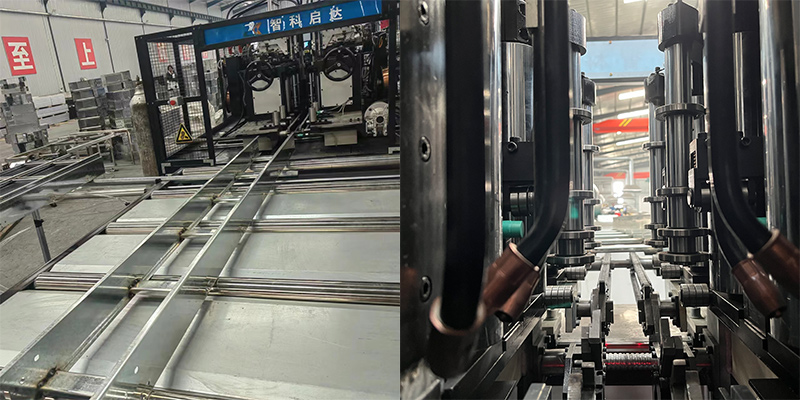

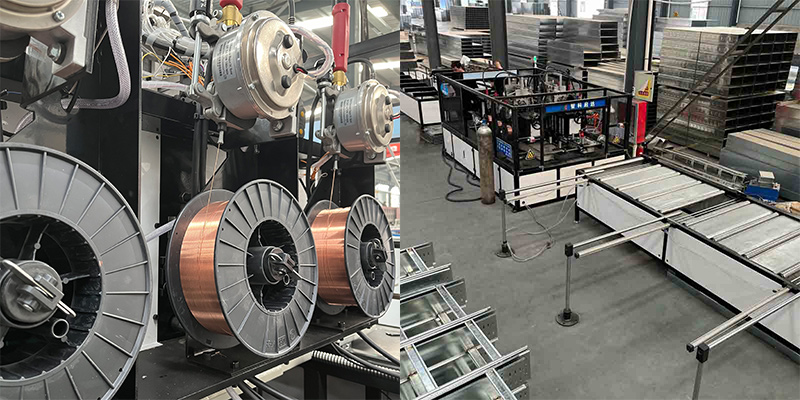

Ladder Cable Tray Automatic Welding Machine

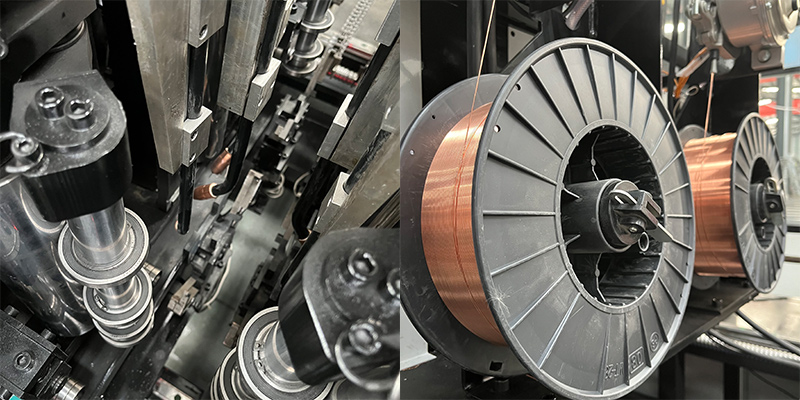

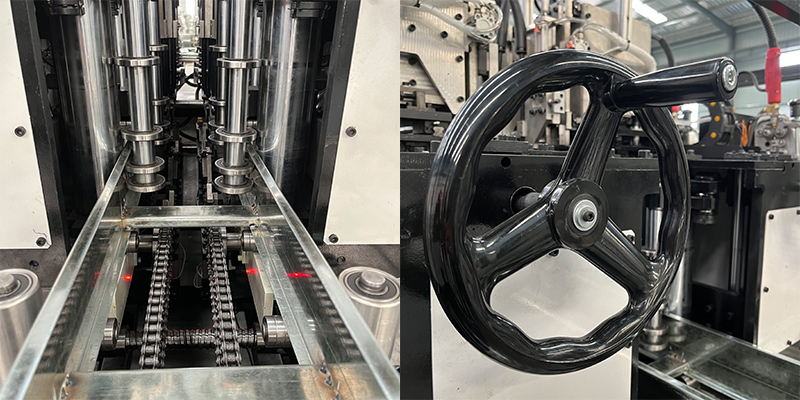

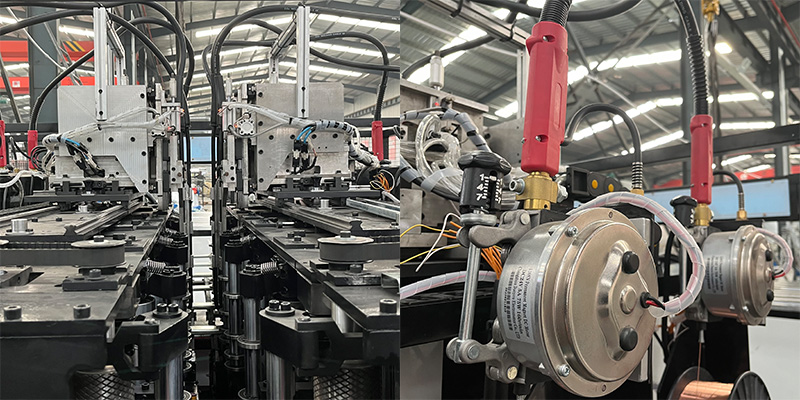

Our welding machine uses six welding guns for simultaneous welding. There are three welding guns on each side distributed on both sides of the fuselage. All transmission methods are driven by servo motors, which greatly improves the accuracy of the motion trajectory. Our welding machine adopts mechanical double positioning, which greatly improves the accuracy of welding. Our welding method can be used for spot welding and pull welding. The 6 welding guns can be controlled arbitrarily and use servo positioning respectively. The ladder support adopts It is a cylinder clamping method, and the ladder side feeding adopts a roller method.

As a high-efficiency and high-precision welding equipment, the fully automatic welding machine will bring the following benefits to users:

1. Improve welding quality: Fully automatic welding machines can achieve precise welding parameter control, resulting in more stable and higher-quality welds. Due to the high repeatability of the robot and the good consistency of the welds, human operating errors can be greatly reduced and the quality of the welding is guaranteed.

2. Improve production efficiency: The automated welding process can be carried out continuously and does not require frequent replacement of welding guns and position adjustments like manual welding. Therefore, work interruptions and waiting times can be greatly reduced, and production efficiency can be improved.

3. Reduce labor intensity: Welding operating conditions are often harsh, with arc light, high temperature and harmful gases present. Using a fully automatic welding machine can reduce the welder’s contact, reduce labor intensity, and improve the working environment.

4. Save human resources: Once the fully automatic welding machine is programmed and set up, it can complete the welding task autonomously, thereby reducing dependence on skilled welders and saving human resources.

5. Reduce material waste: Due to high welding precision, fully automatic welding machines can utilize materials more effectively and reduce the waste of raw materials.

6. Reduce costs: Although the initial equipment investment is relatively high, in the long run, fully automatic welding machines can reduce production costs by improving production efficiency and reducing material waste.

7. Improve safety: Automated equipment can avoid safety risks that welders may encounter during operation, such as electric shock, burns, and inhalation of harmful gases to protect workers' health.

To sum up, the fully automatic welding machine can bring many benefits to users in terms of improving product quality, increasing production efficiency, reducing human resource investment, reducing material waste and improving production safety. With the continuous advancement of automation and intelligent technology, the advantages of fully automatic welding machines will become more obvious in the future.