Cable Tray Automatic Baling Machine

1. Improve production efficiency: The automatic baling machine adopts an automated operating system, which can continuously complete the baling action, greatly increasing the production speed. Compared with manual packaging, it is more efficient and helps shorten the production cycle.

2. Save labor costs: The automatic baling machine can replace multiple manual workers for packaging operations, reducing the company's investment in human resources and reducing labor costs.

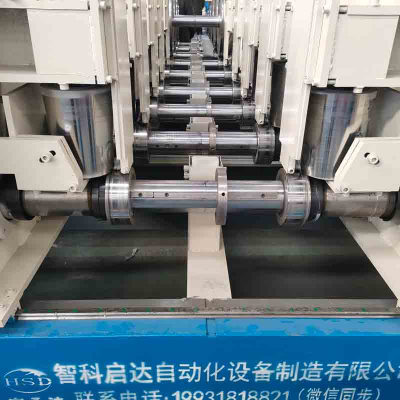

Main components and parameters

Name Description

The main body of the frame is welded from 80x80x3 square tubes

Conveyor belts are all made of thickened anti-skid conveyor belts

Turning lever Q235 plate is laser cut and processed

Material turning lift is powered by pneumatic lifting

The drive shafts are all made of 45# steel, and the surface is plated with Luo.

Slideways adopt precision square rails

Screw 2525 ball screw

Lift servo motor

The hot melt baler

Name Description

Power supply, power 220v/50Hz 500w

Packing speed ≤1.5 seconds/lane

Applicable strap thickness (0.45-1.0) mm*width (9-15) mm

Features: Never lose tape, electronic detection

CNC display, simple operation

Accessories standards are based on Milan, Germany

Traction part

Name Description

The main body of the frame is welded from 80x80x3 square tubes

Mobile power servo motor with reducer and rack and pinion transmission

The slide is made of 45# steel, with high-frequency heat treatment and Luo plating on the surface. It has a thickened aluminum seat and is equipped with an extended slider.

Clamping adopts TN model cylinder to prevent rotation

Palletizing part

Name Description

The main body of the frame is welded from 80x80x3 square tubes

The main body of the robot is made of thickened heavy-duty aluminum profiles.

The manipulator adopts the form of forking first and then pressing to ensure the firmness of grasping and the stability of movement.

The pallet moving roller is made of 45# steel, surface plated, φ45mm solid

Rotating ruler: In order to ensure the squareness of each stack of keels and not scratch the keels when moving, a round ruler is selected and equipped with a rotating bearing inside.

⑤Electricity cabinet

Name Quantity Brand Model

plc 1 display control

Plc expansion 2 display control

1 touch screen display control

Proximity switch several NPN, 24VDC, normally open

Photoelectric switch several NPN, 24VDC, normally open

Low voltage electrical 1 Chint

Servo motor 4 Hechuan 0.75kw

Most equipment motors use servo motors to make the equipment faster and more flexible.

The length of the equipment is about 6 meters, the stacking length is 2 meters, and the total length is about 8 meters.

Width approximately 2.9 meters