The Cable Tray Forming Line

The plates produced by this equipment are formed in one piece, using the production process of one-piece ribs. The bottom is molded to enhance the bending strength; the side panels are uniquely designed, adding two R grooves under the flange, which improves the load-bearing capacity of the flange and effectively prevents side panel instability. In this way, the use of thinner plates with greater load-bearing capacity can be achieved, which plays a role in energy conservation and environmental protection! Products can be customized according to your needs!

Our organisation offers expert custom-made roll forming line offerings to grant clients with environment friendly and correct personalized forming solutions. Whether it is the forming of metal substances or the processing of non-metallic materials, our customized roll forming traces can meet the wishes of a number of industries.

First, our customized roll forming traces are enormously adaptable and flexible. Our crew of experts work carefully with clients to apprehend their particular desires and product requirements, then customized graph and manufacture primarily based on these requirements. We can customise roll forming traces of special specs and models, and personalize exceptional features in accordance to client necessities to make sure specific molding and secure best of products.

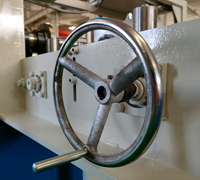

Secondly, our customized roll forming strains use superior science and tools to make certain environment friendly and unique forming results. We are outfitted with superior electrical manage structures and mechanical transmission systems, which allow particular manage and speedy motion of the rollers. We can additionally choose excellent curler substances and structural designs based totally on distinct substances and product necessities to make certain the consistency and excellence of the molding effect.

Additionally, our customized roll forming traces provide a excessive diploma of reliability and stability. We use first-rate substances and stable structural sketch to make certain steady operation and lengthy lifestyles of the equipment. Our gear undergoes strict trying out and excellent manipulate to make certain the balance and reliability of product quality, thereby imparting clients with long-lasting molding solutions.

Finally, our customized roll forming line offerings center of attention on purchaser pride and after-sales support. Our expert crew will furnish complete pre-sales consultation, grant custom-made options in accordance to purchaser needs, and function gear set up and debugging. We additionally supply a full vary of after-sales services, along with gear maintenance, spare components grant and technical support, to make certain that clients can proceed to gain terrific and environment friendly molding production.

In short, our customized roll forming line presents clients with personalized molding options via excessive adaptability, environment friendly and correct molding results, dependable balance and entire after-sales support. No count number what specifications, fashions and substances you want for molding, we can meet your necessities and deliver remarkable molding results and effectivity upgrades to your manufacturing line.