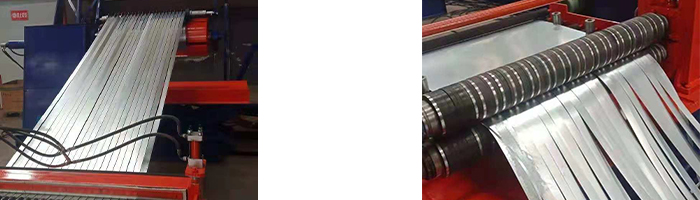

Slitting Machine

This unit is mainly used to continuously and longitudinally cut hot and cold steel strip coils into blanks required for welded pipes or coils with different specifications and widths for other purposes.

Process flow and characteristics:

Winding → Leveling → Disk cutting strip → Waste edge winding → Tension → Coiling → Unloading

1、This machine and equipment is a complete set of process machinery and equipment, which can produce a variety of qualified hot steel coils of different specifications, cold-dip galvanized steel coils, Q235, color steel coils, color-coated coils, aluminum coils, stainless steel coils, etc.

2、This machine adopts more automatic hydraulic controls and pneumatic controls, which reduces the weight of the equipment, simplifies the structure of the equipment, reduces labor intensity, and improves the degree of automation.

3、This machine adopts a high-precision automatic control system to realize partial automation and full-process linkage automation of automatic feeding, uncoiling, slitting, coiling, and uncoiling.

Machine usage:

This machine is mainly used to support and clamp the steel strip coils sent from the coiler. The mandrel can shrink and expand. The centerline of the steel strip coil can be aligned with the centerline of the unit. The maximum supporting weight is 10 tons. (The bearing capacity can be customized at will.) Cone head expansion and contraction method: hydraulic; Power: 11KW

The machine is mainly composed of the reel part, the box body, the expansion and contraction cylinder, etc. The center line of the drum is fixed once when the equipment is installed, and the expansion and contraction of the drum are controlled by the oil cylinder. The lubrication of each rotating and sliding surface of the machine is achieved by injecting grease once during assembly. When the steel coil on the decoiler is almost finished, the shearing speed should be reduced to 3-5m/min. Leveling device upper 5 lower 6 plus front and rear belt shafts, shaft diameter 110, power 11 kilowatts, with fixed length shearing

Precautions:

1、Before feeding the plate head, the unloading truck needs to be driven under the reel, and then the support arm is raised. At this time, the unloading truck cylinder is in a contracted state.

2、The reducer is lubricated by the oil pool, and the rest is lubricated by grease; check the refueling frequently during work to avoid lack of oil.