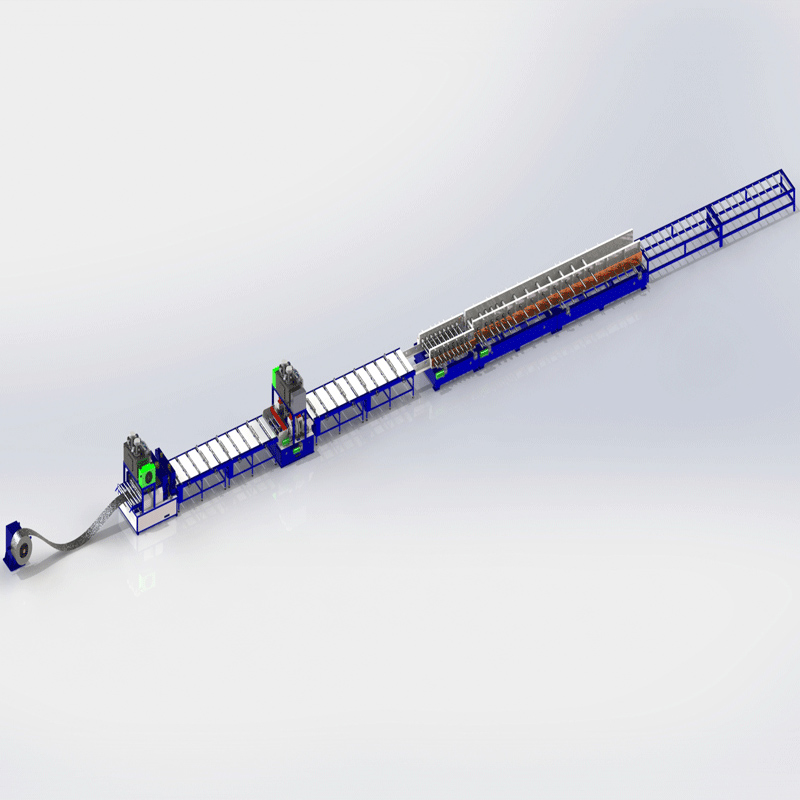

Perforated Cable Tray Forming Machine

The perforated cable cable tray forming machine places the pallet hole mold on the punching machine to complete intensive pallet hole punching. Using the pallet hole mold punching instead of the punch or hydraulic press greatly saves costs.Products can be customized to your needs.

Product advantages

Sturdy machine base and frame for longer service life

High-quality roller mold made of high-quality materials

Automatic Control System

Finished cable trays are cut to precise lengths

Precision punching, accurate hole position

Free the operator's hands and save labor

Easy to install, easy to operate and easy to maintain

high productivity

Roll forming of multiple profiles for cable trays | ladders on one production line

High cost performance

Customized roll forming machines available

Technical data:

1. Applicable plates:

Material-Thickness: 0.5-2.5mm

Raw materials: galvanized steel and black steel plate

2. Working speed: 12 meters/minute

3. Forming station: 25 forming rollers

4. Roller material: Gcr15, the last six passes are Cr12mov, quenched HRC58-62 chrome plated

5. Shaft material: 45# high-quality steel (diameter: *90mm), tempered

6. Drive system: using a chain shaft with a diameter of 100mm

7. Main power belt reducer: 22KW WH Chinese famous brand

8. Cutting: hydraulic cutting Cr12mov

9. Cutter material: Cr12Mov, quenched HRC58-62

10. Hydraulic station power: 7.5KW Wuxi Wanshen Chinese Famous Brand

11. The whole machine is controlled by industrial computer PLC.

12 PLC--Delta

13 touch screen

14 Electrical part

15 Height adjustment through motor and guide rail, controlled by PLC