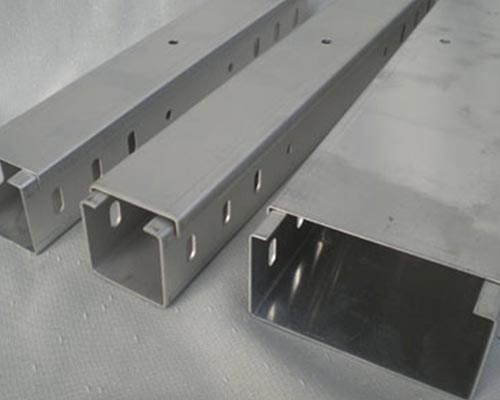

Automatic Perforated Cable Tray Roll Forming Machine

The cable tray forming machine consists of an uncoiler, leveling machine, servo feeding device, punching system, front cutting device, guide device, roll forming machine, rear straightening device and discharge table. With rich and special experience, we can customize cable tray forming machines or cable tray forming production lines according to customers' profile drawings and specifications.

1. Automated Perforation: The machine is equipped with advanced perforation technology, allowing for precise and consistent hole punching in the cable trays. This feature ensures accurate alignment and perfect hole sizes, effectively reducing the need for manual adjustments or rework. 2. Versatile Design: With its flexibility and adaptability, the machine can produce various types and sizes of cable trays. It can be customized to accommodate different dimensions, designs, and material thicknesses, allowing for seamless integration into any cable management project.

3. High-Speed Operation: The fully automatic functionality of the machine enables rapid tray production, enhancing overall productivity. This feature significantly reduces production time and labor costs while maintaining exceptional accuracy and quality. 4. User-Friendly Interface: The machine's intuitive interface enables operators to easily program and control the manufacturing process. The user-friendly design minimizes the complexity of operation and ensures smooth and efficient production. 5. Quality and Durability: Built with reliable and sturdy materials, the machine guarantees long-lasting performance and resistance against wear and tear. Its robust construction ensures consistent quality in the production of cable trays, meeting industry standards and regulations. 6. Increased Efficiency and Cost Savings: As a fully automated system, the machine eliminates the need for extensive manual labor and reduces the chances of human error. This efficiency not only saves time and effort but also optimizes resource utilization and drives down production costs.

Technical Parameters

order number

| project | unit | numerical value |

1 | Material width | Mm | 220~1250mm |

2 | Material thickness | Mm | 0.5~2.0mm |

3 | Material thickness | Galvanized strip steel / galvanized steel plate | |

4 | Equipment running speed | m/min | 12m/min |

5 | powe | Kw | 75KW |