Custom Roll Forming Machine

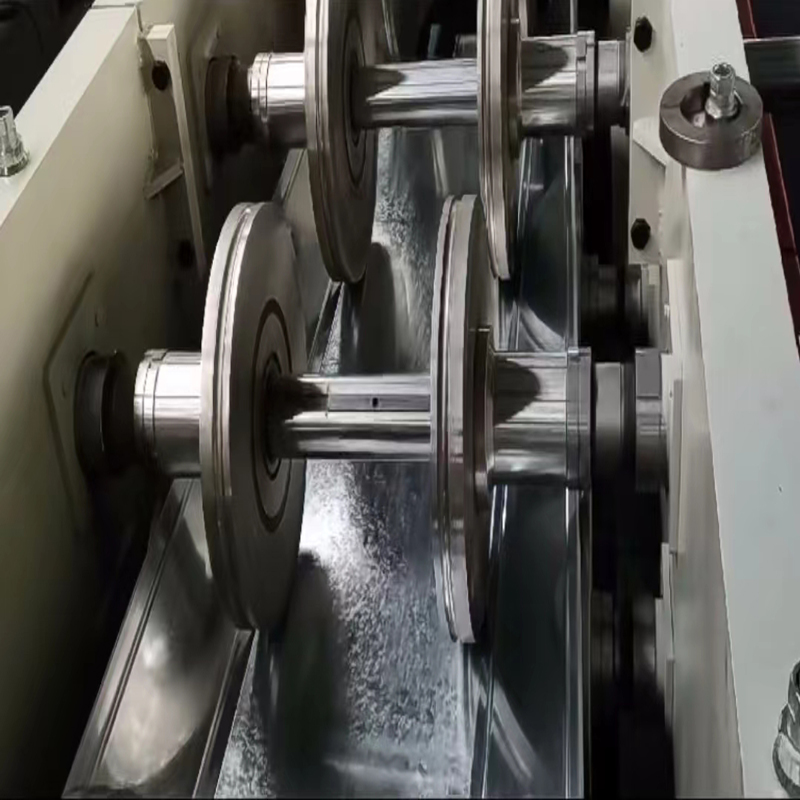

Customers' designs, colors and logos, different plate types, specifications and sizes are all accepted and our experts and professionals continuously work hard to ensure the best performance of the machine. Our rollers are ground, quenched, chromed, finished, polished, and chrome plated 0.05mm to ensure that all rollers are bright, strong, and rust-free, etc., making the roll forming equipment improved and easier to use. During processing, we continuously manage the pressure on the sheet metal so that it no longer damages the base of the sheet and produces the ideal profile.

The device is equipped with a change detection device. In case of emergency, it will alarm and stop operation.

The cable tray roll forming machine is a specialized equipment used in the manufacturing process of cable trays. Cable trays are important devices that provide effective and organized cable management solutions in various industries such as power distribution, telecommunications, and data centers.

This roll forming machine is designed to efficiently and accurately produce high-quality cable trays with consistent shapes and dimensions. It utilizes a roll forming process, where a continuous strip of metal is passed through a series of rollers and gradually shaped into the desired profile of the cable tray. The machine is equipped with various forming stations and cutting tools, allowing it to create different types and sizes of cable trays according to specific customer requirements.

Technical Parameters

order number | project | unit | numerical value |

1 | Material width | Mm | 210~840mm |

2 | Material thickness | Mm | 1.5~2.0mm |

3 | material type | Galvanized strip steel / galvanized steel plate | |

4 | Equipment running speed | m/min | 1-12 m/min |

5 | power | Kw | 75KW |