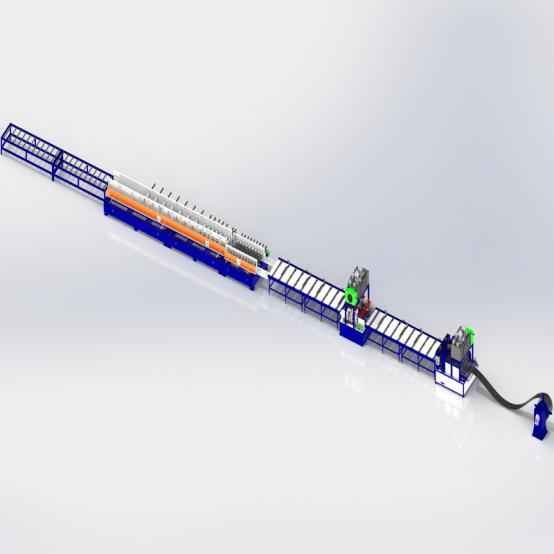

Roll Forming Machines with Complete Production Specifications

This production line can produce cable trays of various specifications by changing the die to complete punching, roll forming, and computer adjustment. A set of rollers can complete various specifications of cable tray products. It can also produce coil materials and a variety of open flat materials with different widths and lengths. , and has a counter.

1、Hydraulic decoiler with a load capacity of 10 tons

2、Roller type active leveling machine,Both the front and rear of the leveling machine are equipped with feed bridge devices. An electronic detection device is installed between the leveling machine and the feeder, which sends a feedback signal to the control system. The control system issues instructions to the variable frequency high-speed motor to change the speed to control the storage capacity of the material tape and achieve the purpose of uninterrupted leveling.

3、CNC feeder

4、Stamping mold,The mold is equipped with a sinking and floating pin guide and a material holding device. Punching is completed step by step, and the conversion of different widths can be completed. The connecting holes on both sides can be punched into through holes, and the bridge molds of the same width can share a mold base.Mold material: Cr12

5、PLC controls fixed-length cutting without waste.

6、Conveying feed rack,Ensure that the metal sheet enters the roll forming machine smoothly. The guide device is mainly composed of horizontal rollers and guide vertical wheels. The guide wheels can be easily adjusted to adapt to various widths of sheets.

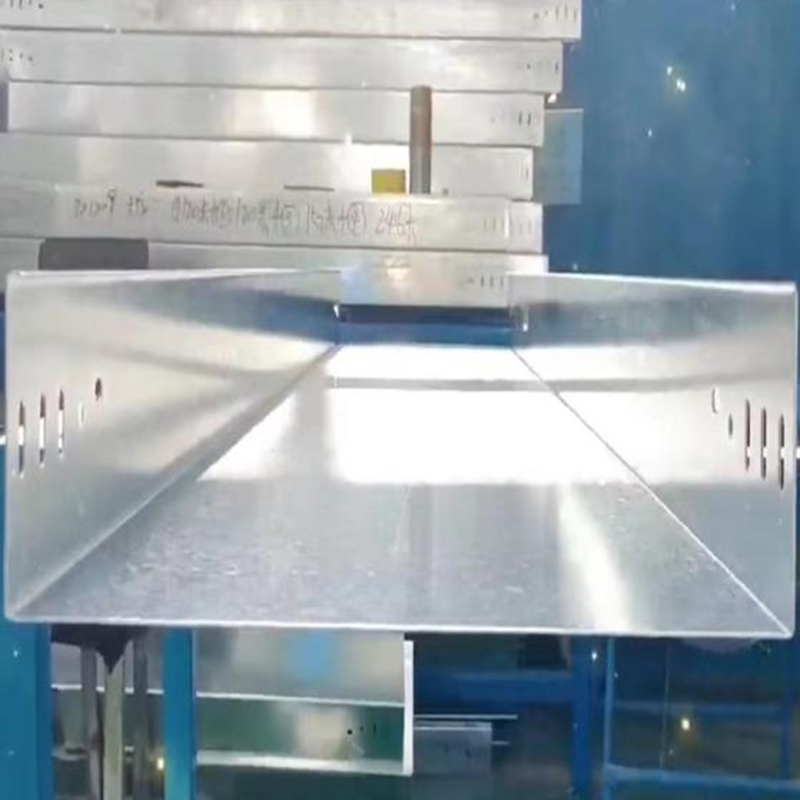

7、Roll forming machine,The stamped and cut metal sheet is gradually rolled into the finished cable tray through 25 passes of rollers. It consists of a speed-adjustable AC motor, a reducer, a high-precision rolling linear guide, a left and right transmission box, a transverse adjustment mechanism, and a roller set. A set of rollers can complete the formation of cable trays of various specifications, and the variety can be changed by adjusting the position of the left and right rollers. The bed and transmission box adopt welded structures and are stress-relieved; the gears adopt hard tooth surfaces; the main machine structure is manufactured using forging technology, with higher precision.

8、The unloading rack is unpowered and workers manually receive materials.