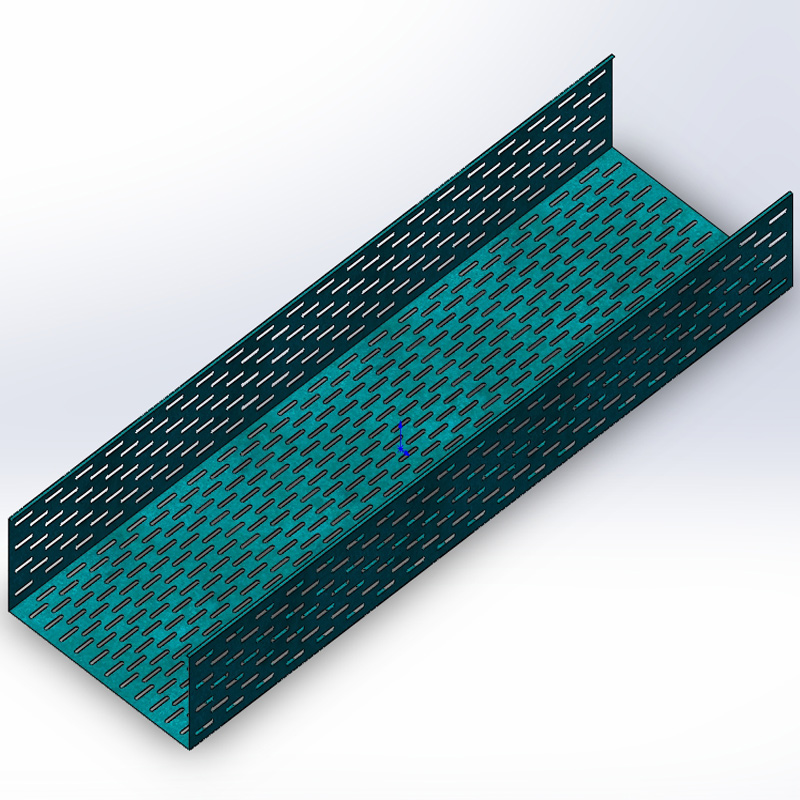

Hydraulic Punching Cable Tray Marking Machine

Traditional handmade cable trays are inefficient and unable to meet the evolving market demands. The emergence of cable tray forming machines solves this problem. At present, cable tray forming machines have core technologies such as ultra-high speed, forming, computer cutting, and automated punching, which can significantly improve the manufacturing efficiency of cable trays.

In the future, with the rapid development of intelligent technologies such as artificial intelligence and the Internet of Things, cable tray forming machines will be further upgraded to assume the role of intelligent control systems. Realize remote monitoring and fault analysis of equipment to improve manufacturing efficiency and stability.

Serial number | main component | Configuration | |

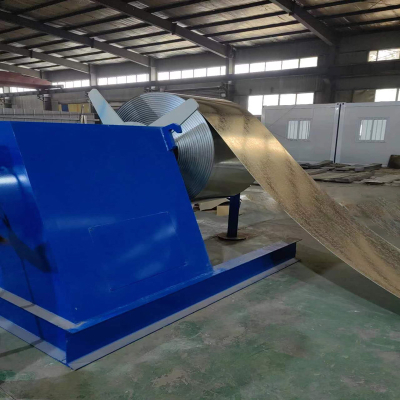

1 | 1. Hydraulic core expansion 4. Distribution box (frequency conversion control, slow start and slow stop) 2. Electric discharge 5. Hydraulic 3KW set 3. Bearing capacity 12 tons | ||

2 | Servo leveling feeder | 1. Feeding code positive mechanism (positive and negative lead screw) 2. 9 correction rollers, 4 up and 5 down 3. 4 feeding rollers, 2 up and 2 down 4. Servo feeding | |

3 | Pneumatic gantry punch | 1. Pneumatic gantry punch 2. 1 set of combined grinding tools, mechanically molded 3. Bottom rib and side bulging molding 4. Pallet hole punching 5. Cut off 6. Shock absorbing pad 7. Mold transfer device | |

4 | Section A high-speed platform | 1、1. High-speed platform 6 meters (1 powered, 1 unpowered) 2、2. Frequency conversion control 3、Positive and negative screw width adjustment | |

5 | Hydraulic punching | 1、1. Connection hole punching 2、2. Seven-character buckle stamping 3、3. A set of hydraulic system 7.5KW+7.5KW 4、4. Punching die: pneumatic switching of single and double row punches stamp | |

6 | Section B high-speed platform | 1、1. High-speed platform 6 meters (1 powered, 1 unpowered) 2、2. Frequency conversion control 3、Positive and negative screw width adjustment | |

7 | Roll forming part | 1. Spindle φ80mm, surface hard chrome plated 5. Extended feeding guide 2. 35 rows of forming rollers (single and double sides) 6. 1 set of flat surface straightening after forming 3. The main machine is divided into 3 sections 7. Roll material: GCR15 4. Long ribs on the side 8. Electric feeding | |

8 | Unloading rack | 1、2 passive unloading racks | |

9 | Control cabinet | 1. The entire line adopts PLC control and touch screen human-machine interface to realize human-computer interaction. 2. Hardware configuration: Power distribution cabinet operation console, manual operation panel and wireless remote control next to the machine 3. Operation mode: manual/automatic. In the manual state, it can operate as a stand-alone machine for easy maintenance; in the automatic state, it can operate across the entire line; it is equipped with an emergency stop button, making it easy to handle emergencies and ensuring the safety of equipment and operators | |