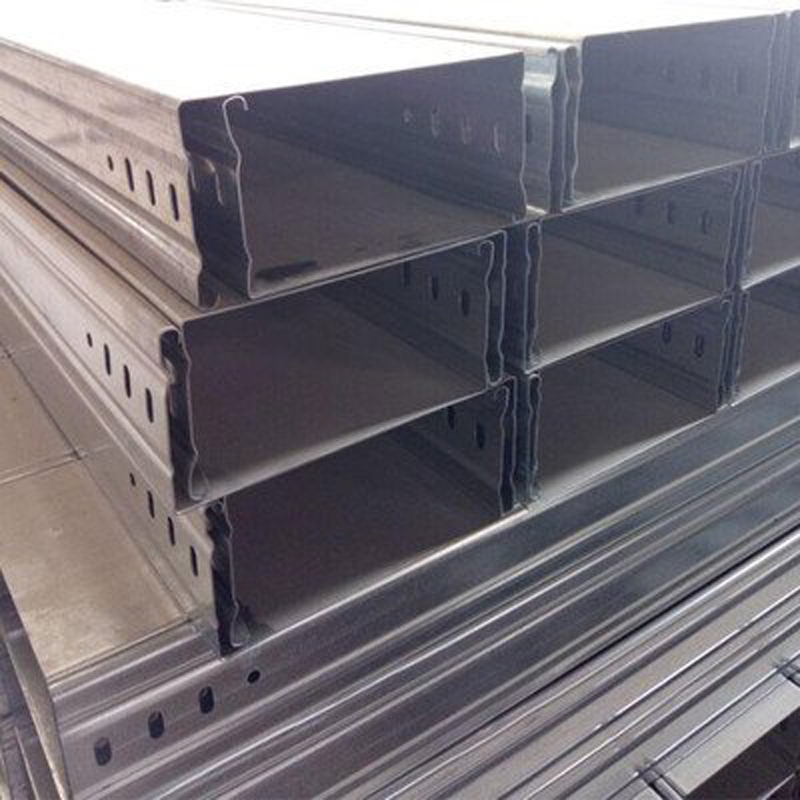

Medium-sized Cable Tray Forming Machine

This cable tray roll forming machine is a machine carefully designed by Zhike Qida. It can produce plates within 840mm wide, and the minimum can produce more than 240mm to meet your order production needs, so that you can invest less money Come and get this equipment for production. At the same time, we will also customize the model according to the size of your order. The larger the machine, the higher the price, and vice versa.

main component

1、Open rolling machine ,hydraulic core, bearing 5 tons, distribution box (frequency conversion control slow up slow stop), hydraulic 3KW set

2 , 13 roller leveling, hydraulic system 111 KW 2 group electric valves, 7.5KW motor , Hydraulic cutting, tray punching (optional)

3, section A high speed platform , 2 high speed platform, width adjustment of positive and reverse wire rod, frequency conversion control,

4, punching machine,mold pneumatic transformation single and double row, oil cylinder heavy engineering cylinder, typing (trademark) (optional)

5, section B high-speed platform ,positive and reverse wire rod width adjustment, frequency conversion control

6, roller press forming part , spindle φ 70mm, surface plating hard chromium, forming roll 25 rows, side bottom surface reinforcement, forming plane straight 1 set, roll material: GCR 15

7, unloading frame , passive unloading frame 2 pieces

This gear is a medium-sized cable trough roll forming machine. It is an environment friendly computer for the manufacturing of medium-sized cable trough systems. It is designed for crimping and shaping sheet metallic into cable duct sections, offering a dependable and budget friendly answer for cable management. The tools is geared up with superior technological know-how and facets to make certain precision and satisfactory of the manufacturing process. It consists of a curler machine that cautiously courses sheet steel thru a collection of rollers, making use of stress to structure the preferred shape. In addition, the gear is outfitted with slicing equipment to reduce sheet metallic to the required length, ensuing in particular and steady cable duct cross-sections. A key benefit of medium-sized cable trough roll forming tools is its versatility. It can deal with a range of substances such as galvanized steel, stainless metal and aluminum, permitting producers to produce cable duct structures appropriate for exclusive applications. In addition, the tools is designed to accommodate exceptional sizes and specifications, offering manufacturing flexibility. Another gain of this tools is its excessive manufacturing capacity. Through its computerized operation and environment friendly curler system, it can produce cable duct sections quicker than standard guide methods. This no longer solely will increase productiveness however additionally reduces labor costs, making it a low cost answer for cable trough manufacturing. In addition, medium-sized cable trough roll forming tools is common and handy to operate. It comes with a consumer interface that allows the operator to set the required parameters such as sheet size, bending attitude and slicing length. The gadget is additionally geared up with security facets to make sure operator safety. In summary, medium-sized cable duct roll forming gear is a dependable and environment friendly answer for the manufacturing of medium-sized cable trough systems. Its superior technology, versatility, excessive manufacturing ability and effortless layout make it an essential device for cable duct manufacturers. With its precision and cost-effectiveness, this gadget helps in seamless cable administration in a number of applications.