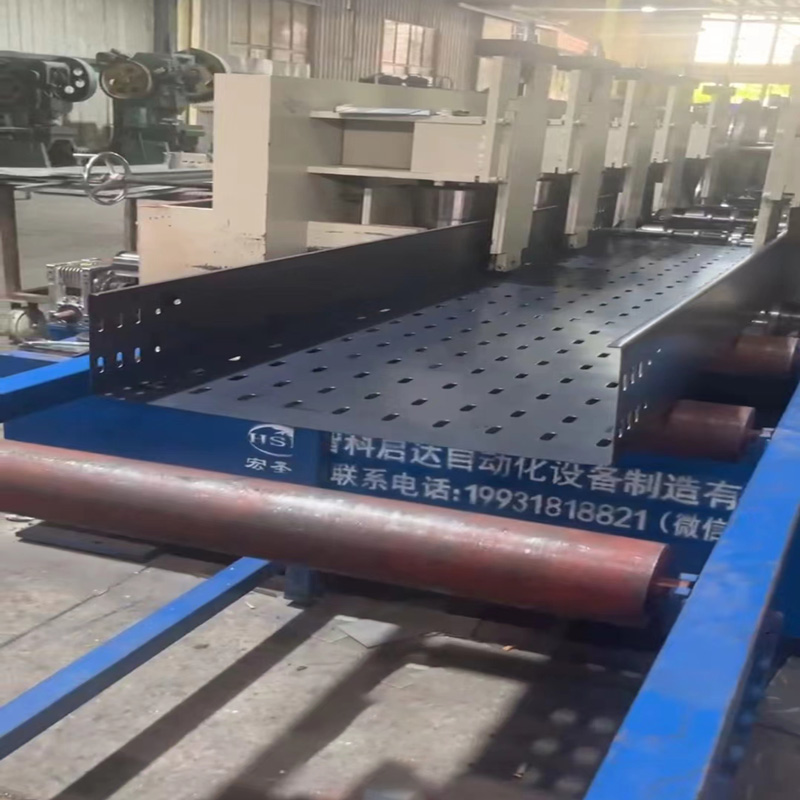

100mm-800mm Punching Cable Tray Forming Machine

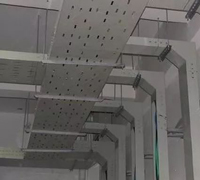

Perforated cable trays are most widely used in petroleum, chemical industry, electric power, light industry, television, telecommunications and other fields. It has the advantages of light weight, large load-bearing capacity, beautiful appearance, simple structure and easy installation. Suitable for the erection of power cables and the laying of management cables. It is also suitable for manufacturing punched cable trays with particularly simple shapes and arrangements. We position the die on the leveling device to complete the punching of the pallet holes. If a large number of dense and irregular punching holes are required, we will consider using a high-power hydraulic press or punch press to ensure manufacturing speed and stability.

main component

1、Open winding machine,load-bearing ten tons of electric hydraulic open rolling machine

2、Leveling and cutting machine,13 roller leveling, hydraulic cutting, tray punching Section A high-speed

3、platform, high-speed platform 2 branches, frequency conversion control

4、Punch machine,hydraulic system (7.5kw2 sets), mold pneumatic conversion single and double row, oil cylinder heavy engineering cylinder, typing (trademark Section

5、 high-speed platform,high-speed platform 2 (1 electric 0.75kw, 1 passive), the width of the positive and reverse wire rod is adjusted

6、 Roller forming part,spindle φ 80mm, surface coated hard chromium, forming roller 25 rows, main divided into 3 sections, 7.5 kW motor 3, extended feed guide position, forming plane straight 1 set, roll material: GCR15, electric feed (1.2 kW servo motor 1)

7, unloading frame,passive unloading rack 2

Technical Parameters

order number

| project | unit | numerical value |

1 | Material width | Mm | 220~1250mm |

2 | Material thickness | Mm | 0.5~2.0mm |

3 | Material thickness | Galvanized strip steel / galvanized steel plate | |

4 | Equipment running speed | m/min | 12m/min |

5 | powe | Kw | 75KW |