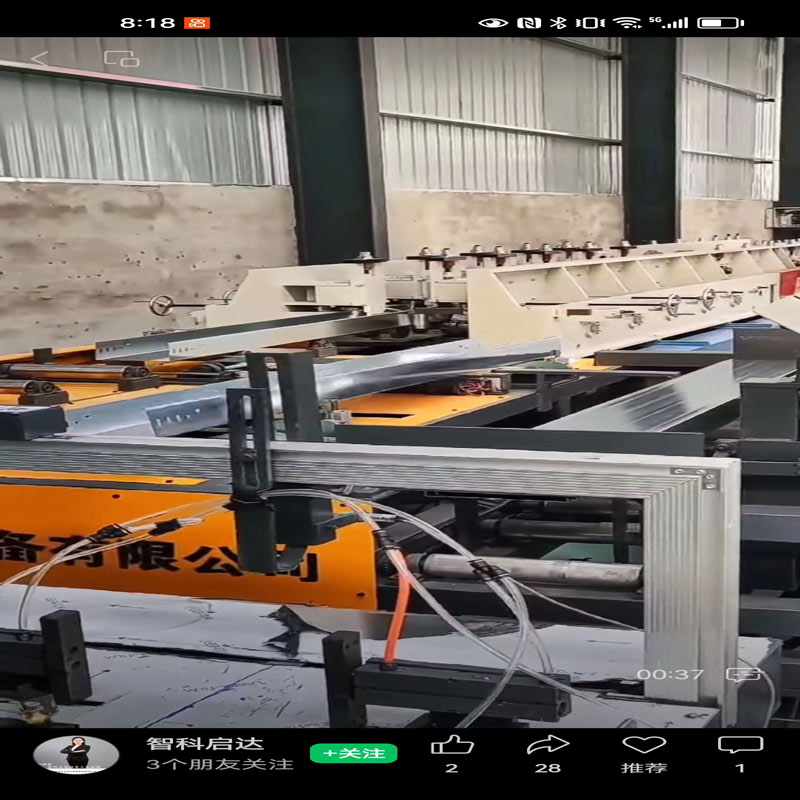

Medium Cable Tray Perforation Making Machine

Cable tray manufacturing machines are specially designed for large-scale manufacturing of cable tray structural troughs. We will make technical choices for you completely based on your needs, such as color, logo, product specifications produced, punching size, layout, etc. We use Schneider PLC systems: ensuring high precision and easy operation! Fully computerized control: Just enter the size and range of the panels you need, and the computer will start working according to your order. We will randomly send some vulnerable parts to ensure that your manufacturing can proceed smoothly!

main component

1、 open rolling machine , manual core rise, electric material discharge, load-bearing 4 tons, distribution box (frequency conversion control slow slow stop)

2、 leveling machine , 11 roller leveling (up 3 down 4), power 4.0KW

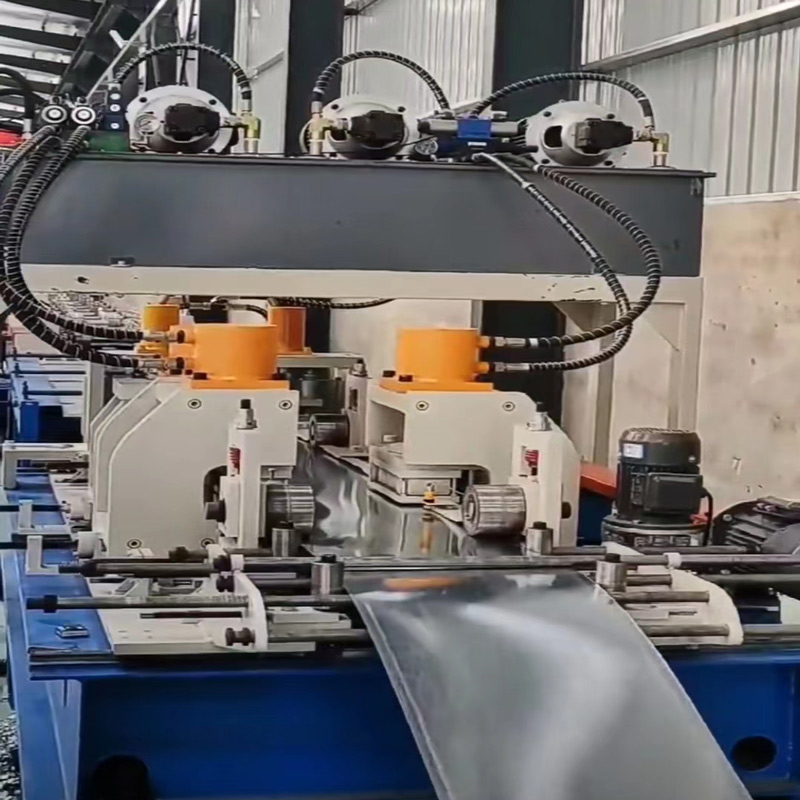

3、 punching and cutting machine , feed code forward mechanism (positive and reverse screw), hydraulic punching, hydraulic cutting, punching die manual pin transform single and double row, typing (trademark) (optional)

4、 high-speed platform , 1 high-speed platform, frequency conversion control, forward and reverse wire rod width adjustment

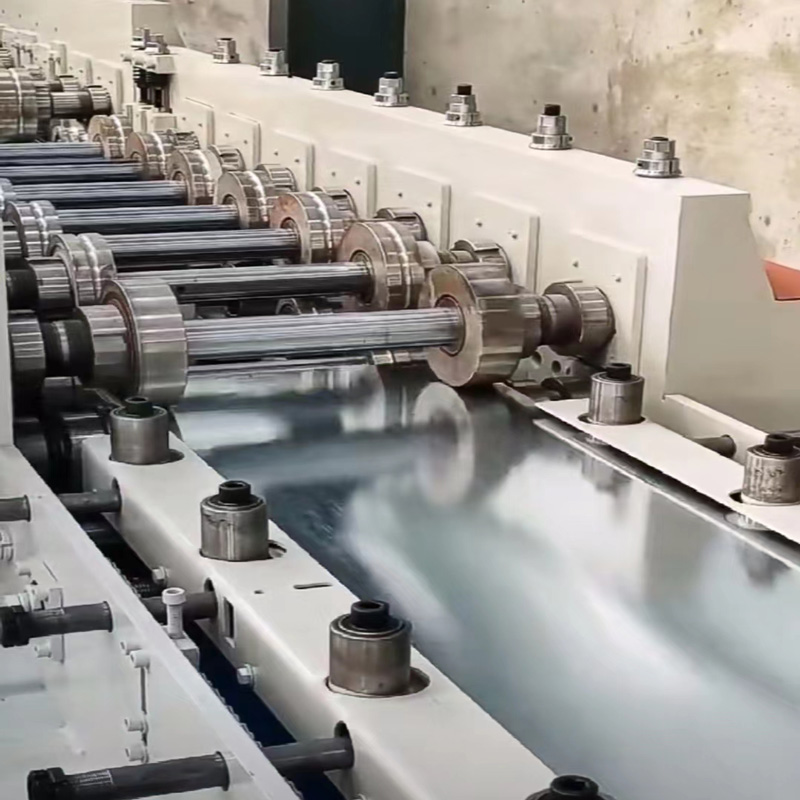

5 、roller press forming part , spindle φ 50mm, surface coated hard chromium, forming roll 21 row, the host is divided into 3 sections, side reinforcement, extended feed guide position, forming plane straight 1 set, roll material: GCR15, electric feed (optional)

6 、unloading frame , passive unloading rack: 1 branch

Technical Parameters

order number | project | unit | numerical value |

1 | Material width | Mm | 160~550mm |

2 | Material thickness | Mm | 0.5~1.5mm |

3 | material type | Galvanized strip steel / galvanized steel plate | |

4 | Equipment running speed | m/min | 1-12 m/min |

5 | power | Kw | 48KW |