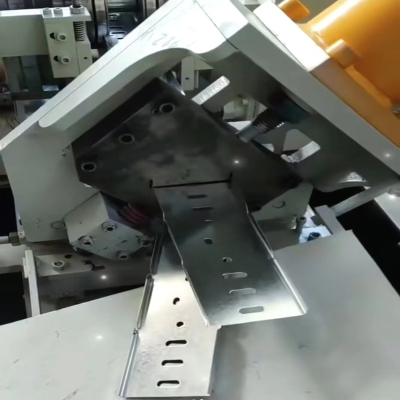

1000mm Cable Tray Forming Machine

The cable tray forming machine consists of an uncoiler, leveling machine, servo feeding device, punching system, front cutting device, guide device, roll forming machine, rear straightening device and discharge table. With rich and special experience, we can customize cable tray forming machines or cable tray forming production lines according to customers' profile drawings and specifications.

The total length of this production line is 42 meters. It can produce metal sheets of 220-1450mm with a thickness of 0.5-3.0mm. It is equipped with two sets of punching dies with large and small gaps. The production speed is 12 meters per minute. The entire assembly line is leveled by an uncoiler. It consists of cutting part-conveying platform-punching machine-conveying platform-roller forming host-receiving frame.

The equipment is equipped with a decoiler with a load capacity of 10 tons, hydraulic core expansion, and electric feeding, which is more convenient to operate. Below is the leveling and cutting. Our leveling machine will straighten the plate of the metal coil and then cut it into the required length. , the metal sheet after cutting enters the punching machine through the transfer platform to complete the punching of connecting holes, seven-character button holes, etc., and then enters the roll forming process. Our material inlet is equipped with a fiber optic probe, which will process the metal sheet according to the shape of the metal sheet. The width is automatically adjusted, there are 25 rows of forming rollers, the main shaft diameter is 80mm, and the surface is hard chrome plated to ensure the perfect outline and gloss of the cable tray.

The size of all parts will be customized according to your needs, please contact me if you need it!