Anti-seismic Bracket Production Line

Seismic bracing equipment is a critical tool used to strengthen and support building structures against the forces of earthquakes. It is designed and manufactured to provide reliable, proven solutions to enhance the seismic resistance of buildings and ensure the safety of people and property in the event of an earthquake. This equipment uses high-quality materials and workmanship to ensure the strength and stability of the bracket and can withstand the huge impact generated during earthquakes. The support structure design is flexible and suitable for various building structures and geological environments to meet the needs of different projects.

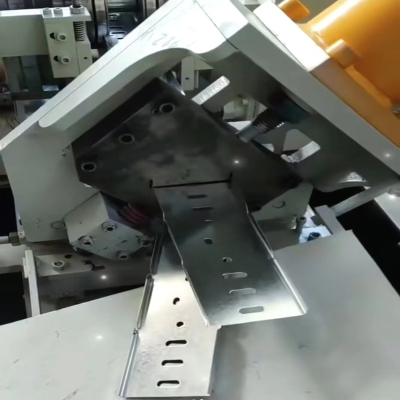

Equipment composition: decoiler → forming host → online punching and cutting → splicing table

1. Uncoiler: vertical manual tensioning (bearing 3 tons)

2. Forming host: 5-roller leveling, spindle diameter 80mm; material 40CR, quenching and tempering treatment

Forming passes: 23 passes (16 sets of side rollers, 1 set of straightening rollers)

Main motor power: 18.5KW×2, equipped with K series reducer

Transmission mode: gearbox transmission (quantity 21 units, 160 type gearbox)

Arch: high-precision cast steel arch; bearing brand: Renben (double bearings for front and rear arches)

Bottom seat: Q235 steel plate welding, gantry milling machine processing platform after failure treatment

Roll material: CR12mov (CNC finishing after vacuum heat treatment)

3. Punching: online hydraulic punching after forming (servo does not stop), hydraulic pump station power 5.5KW×2

Punching form: double cylinder punching; servo motor power 1.5KW

4. Cutting: The servo does not stop and the flying saw cuts without burrs.

5. Production speed: ≦25m/min

6. Material receiving table: 6 meters in length (square tube welding) drum type

7. Electronic control: Inverter brand: Shanghai Zhongchen; Servo system: Shanghai Zhongchen; Touch screen: Wuxi Xinjie; Low voltage: Chint; Encoder: Omron; PLC: Taiwan Delta

Hydraulic brand: Beijing Huade

3. Rolling model of the unit: U-shaped 41×41-72, thickness 2-2.5mm

4. The production line is 34 meters long × 3.2 meters wide × 1.7 meters high

5. Others: Working voltage: 380V/50HZ/3 phases

Total power: about 50KW

Hydraulic oil: 46# anti-wear hydraulic oil

tooth