Solid Bottom Metal Forming Machine

The cable tray forming machine has a flexible design and can be customized and produced according to different needs. It can easily handle cable tray covers, ladder-type cable tray beams and longitudinal beams of various specifications and models or special shapes. It is widely used in electric power, communications, data network and other industries.

main component1、Open winding machine,load-bearing ten tons of electric hydraulic open rolling machine

2、Leveling and cutting machine,13 roller leveling, hydraulic cutting, tray punching Section A high-speed

3、platform, high-speed platform 2 branches, frequency conversion control

4、Punch machine,hydraulic system (7.5kw2 sets), mold pneumatic conversion single and double row, oil cylinder heavy engineering cylinder, typing (trademark Section

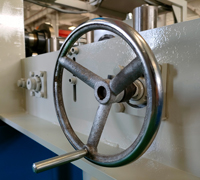

5、 high-speed platform,high-speed platform 2 (1 electric 0.75kw, 1 passive), the width of the positive and reverse wire rod is adjusted

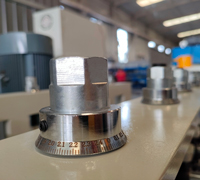

6、 Roller forming part,spindle φ 90mm, surface coated hard chromium, forming roller 25 rows, main divided into 3 sections, 7.5 kW motor 3, extended feed guide position, forming plane straight 1 set, roll material: GCR15, electric feed (1.2 kW servo motor 1)

7, unloading frame,passive unloading rack 2

The metal sheet roll forming machine is a professional equipment used for metal sheet processing. Through the rotation of the rollers and the cooperation of auxiliary tools, the metal sheet is pressed and formed according to the preset shape and size. Our sheet metal roll forming machines have excellent performance and reliable working results to meet a variety of sheet metal processing needs.

First of all, our sheet metal roll forming machines use advanced transmission systems to achieve high work efficiency and precision. The equipment is equipped with multiple sets of rollers, which are precisely designed and adjusted to press and shape metal sheets quickly and smoothly. The high-speed and precise processing process ensures the consistency and stability of the product.

Secondly, our sheet metal roll forming machines are highly adaptable and flexible. The equipment can flexibly adapt to different processing needs by replacing rollers and adjusting parameters according to the characteristics and processing requirements of different metal materials. Whether it is steel plate, aluminum plate, copper plate, etc., or thin plate or thick plate, it can be processed effectively by our equipment. In addition, the equipment can also achieve molding of various shapes and sizes to meet customers' diverse needs for product design.

In addition, our sheet metal roll forming machines offer a high degree of accuracy and stability. The equipment uses advanced sensors and control systems to enable precise control of the position, pressure and speed of rollers and auxiliary tools. The processed products have the advantages of accurate size and uniform shape, and can meet customers' product quality requirements.

Finally, our sheet metal roll forming machines are designed with safety and reliability in mind. The equipment is equipped with multiple safety protection devices, such as safety gratings, emergency stop switches, etc., to ensure the safety of operators. At the same time, the equipment uses high-strength materials and solid structural design to ensure the stability and durability of the equipment.

To sum up, our sheet metal roll forming machines are efficient, precise, flexible, highly precise and stable. Whether it is metal processing, manufacturing, construction and other fields, our equipment can provide you with high-quality processing solutions, improve production efficiency, reduce costs, and bring stable and reliable support to your projects.