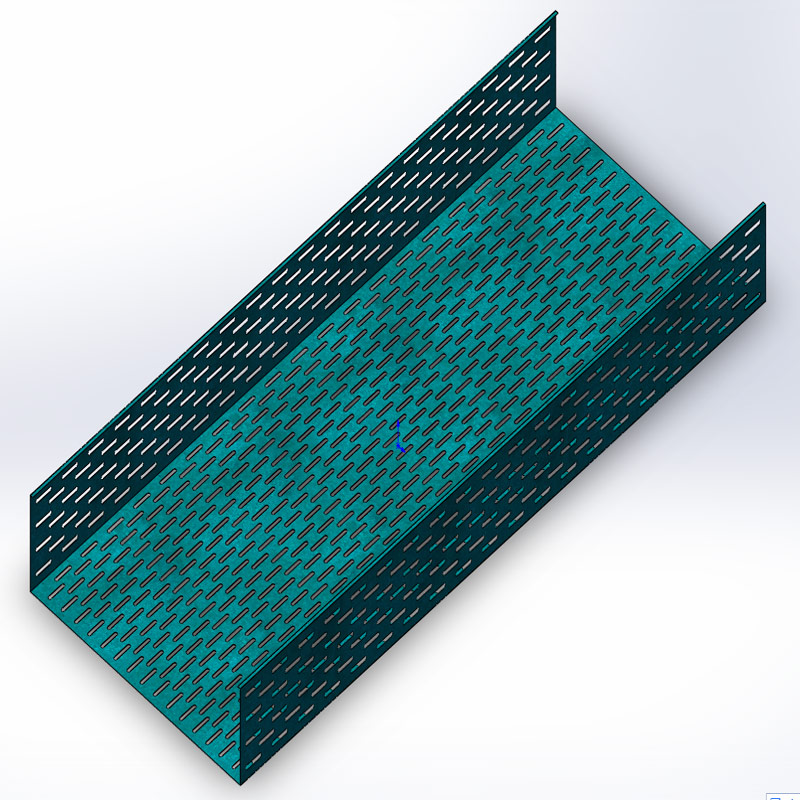

LW-Perforated Cable Tray Forming Machine

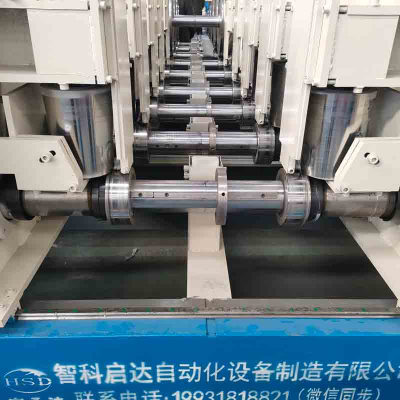

Using a perforated cable tray forming machine, the operator needs to first place the metal sheet on the workbench of the forming machine, and then adjust the mold shape of the forming system as needed. After starting the forming machine, the metal sheet will be transferred to the forming system. Through the action of the upper die wheel, lower die wheel and pressure roller, the metal sheet is pressed into the required shape to form the cross section of the cable tray. Finally, the cutting system will cut the formed cable tray into corresponding sections according to the set length.

The perforated cable tray forming machine has the advantages of high forming efficiency, easy operation, and high forming accuracy. It is widely used in cable laying projects in the fields of power, communications, construction, etc.

The perforated cable tray forming machine is a piece of equipment used to make cable trays. Cable tray is a metal frame structure used to support and protect cables. It is often used for cable laying inside buildings.

The perforated cable tray forming machine mainly consists of the following parts:

Hydraulic decoiler, leveling and cutting integrated machine, punching machine, roll forming host, etc.

Technical data:

1. Applicable plates:

Material-Thickness: 1-3mm

Raw materials: galvanized steel and black steel plate

2. Working speed: 12 meters/minute

3. Molding stations: 25 stations

4. Roller material: Gcr15, quenched HRC58-62 chrome plated

5. Shaft material: 45# high-quality steel (diameter: *90mm), tempered

6. Drive system: using a chain shaft with a diameter of 100mm

7. Main power belt reducer: 22KW WH Chinese famous brand

8. Cutting: hydraulic cutting Cr12mov

9. Cutter material: Cr12Mov, quenched HRC58-62

10. Hydraulic station power: 7.5KW Wuxi Wanshen Chinese Famous Brand

11. The whole machine is controlled by industrial computer PLC.

12 PLC--Delta

13 touch screen

14 Electrical part

15 Height adjustment through motor and guide rail, controlled by PLC